- Joined

- Sep 9, 2012

- Messages

- 410

- Location

- Germany, Wiedemar

- First name

- Joachim

Machinery:

Zetor 2011, Zetor 3045, Zetor 5011, Zetor 7340 Economic

How do you shift a unsynchronized transmission, such as on older Zetor tractors? :think2:

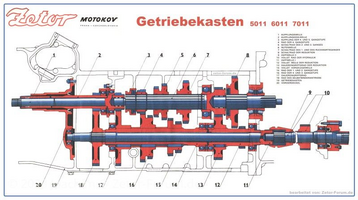

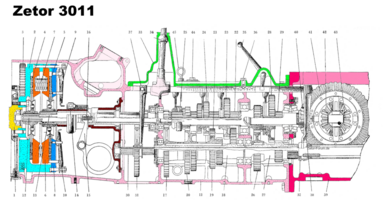

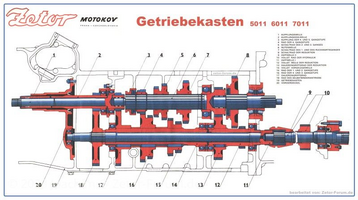

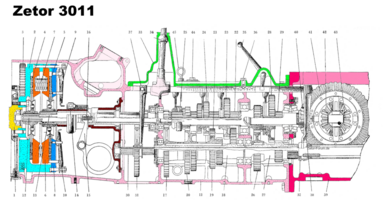

Zetor Transmission diagrams in sectional view

With a little practice, shifting an unsynchronized gearbox is relatively easy:

Approach:

On the level without load, do not choose the lowest gear; with a 5-speed transmission you usually start with 4th gear, with a 4-speed transmission you use 3rd gear.

Upshift:

Using the example of 3rd to 4th gear:

1. Press the clutch, take out 3rd gear

2. Release clutch (gear lever in neutral)

3. Press the clutch, engage 4th gear

4. Let the clutch come back

Downshift:

1. Depress the clutch and take it out of gear

2. Release clutch (gear lever is in neutral)

3. briefly accelerate

4. Depress the clutch and select a lower gear

5. Release clutch

Downshifting is much more difficult than upshifting - but again it's just a matter of practice.

Note: On some Zetor models a partially synchronized transmission was installed, where the 2 highest gears in a group were each synchronized. E.g. with the UR1 series "2" (5211-7745T), such as the Zetor 5211 etc. Some Zetor models also have a gear brake, such as. 4911... and 5011 to 7745T, which makes shifting the unsynchronized gearbox easier, provided they are not worn and Go to:

View: https://youtu.be/_pD9R9Tqt8w

With synchronized transmission:

Go to: https://youtu.be/VI6nPhnHHcw

Why, on the other hand, are “synchronized” transmissions easier to shift?

Go to: https://youtu.be/o0WQh3VYLPM?t=18s[/SIZE ]

Zetor Transmission diagrams in sectional view

With a little practice, shifting an unsynchronized gearbox is relatively easy:

Approach:

On the level without load, do not choose the lowest gear; with a 5-speed transmission you usually start with 4th gear, with a 4-speed transmission you use 3rd gear.

Upshift:

Using the example of 3rd to 4th gear:

1. Press the clutch, take out 3rd gear

2. Release clutch (gear lever in neutral)

3. Press the clutch, engage 4th gear

4. Let the clutch come back

Downshift:

1. Depress the clutch and take it out of gear

2. Release clutch (gear lever is in neutral)

3. briefly accelerate

4. Depress the clutch and select a lower gear

5. Release clutch

Downshifting is much more difficult than upshifting - but again it's just a matter of practice.

Note: On some Zetor models a partially synchronized transmission was installed, where the 2 highest gears in a group were each synchronized. E.g. with the UR1 series "2" (5211-7745T), such as the Zetor 5211 etc. Some Zetor models also have a gear brake, such as. 4911... and 5011 to 7745T, which makes shifting the unsynchronized gearbox easier, provided they are not worn and Go to:

View: https://youtu.be/_pD9R9Tqt8w

With synchronized transmission:

Go to: https://youtu.be/VI6nPhnHHcw

Why, on the other hand, are “synchronized” transmissions easier to shift?

Go to: https://youtu.be/o0WQh3VYLPM?t=18s[/SIZE ]

Last edited: