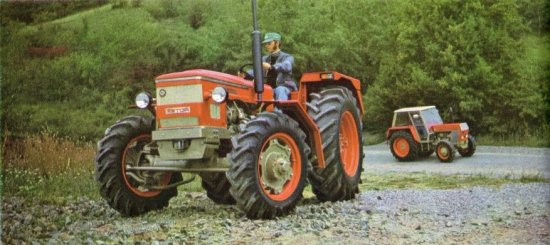

In 1972, a major review of the UR1 models took place. The market demanded not just for a versatile source of power, but also for more load carrying capacity and traction. The seven series was Zetor's answer: three base models, a new three cylinder engine with a wider 100 mm bore was presented in the model 4712, the four cylinder 3.1 liter engine from the previous model, designated 5501, was continued in the 5711 and a new four cylinder engine, designated as 6701 was built in the 6711 tractor, sharing the 100 mm bore of the three cylinder 4701 engine. Because of strengthened axles and frames as well as the weight of the reinforced components, the whole range moved up a tractive class. modernisations and options: Not just the engines were stronger, but also crucial parts of the driveline: The size of the new developed portal half axles, bearing size and housing strength was increased conciderably and the width of the reduction gears was doubled. The weld-assembled structure in front of the engine, that carries the front axle and several underbonnet parts, was changed for a heavy casting. The casting had better attachment points for loaders and other front mounted equipment, was stronger to carry these implements, but also added weight and increased the wheelbase, to aid the tractor's balance when it works with heavy rear mounted implements. Also the front axle had stronger hubs, recognizable for having 6 wheel bolts instead of four.

The strongest four wheel driven tractors, the 6745 and 6748, had a new front axle, with stronger planetary hubs and differential, and a bigger vertical load capacity. The wheel flanges were made of a massive plate of cast-iron, to balance the tractor to a weight distribution of 43% front / 57% rear. The very good weight distribution allowed to achieve a maximum traction from the front wheel drive. Option was an automatic front axle differential lock. This axle was used on the UR1 tractors until 1996.

The PTO had,

just like previous models, a ground speed gear, which meant that the

PTO shaft could be driven via the 5 speed main gearbox. To use these

5 PTO speeds, 250 to 1331 PTO rpm stationary without forward movement of the tractor,

the high and low range gear lever should be put in neutral position. This

option was important for the few farmers that bought a new tractor but

still wanted to drive a threshing mill via an optional PTO driven belt

pulley attachment that could be bolted onto the rear end. Also stationary

PTO work could benefit of this, because there is always a matching speed

to get the right speed with the best fuel economy. However an unknown

manufacturing error in some tractors could give problems with the gearbox

lubrication. Because the 5 speed PTO wasn't much used by the average

farmer, this problem is not very well known or described.

The hydraulic operated drum brakes remained the same as on older series, but the independent operation by two pedals, became the standard setup. On request, a trailer air brake could be fitted. This air brake needed only a valve and pressure actuator, because the UR1 tractors are fitted standard with air compressor. Technical specifications

The 2511 was the last two cylinder engine manufactured in Brno, which was produced to 1977 complementary to the modernised 7 series, 4712 to 6748. © DmdB 2002-2003 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||